FAQ

Frequently asked questions

On this page you will find a list of the “frequently asked questions” with their answers. And if you can’t find some information, you can ask us a question using the FAQ form.

FAQs

If the teknow wizard issues warnings, there are details in your drawing that may not be able to be produced in optimal quality. This mainly applies to narrow webs. In many cases, the workpiece can still be produced. Sometimes the quality of a detail is not important either, for example when it is just a matter of bars to connect the actual parts. It is not possible for the software to identify such cases. You can then decide how you want to proceed – produce anyway, or redesign. This page gives you assistance with a few examples.

Note: If you produce a drawing with warning messages, defects in the areas marked with the warnings are not grounds for complaint. Production takes place at your own risk with regard to these locations.

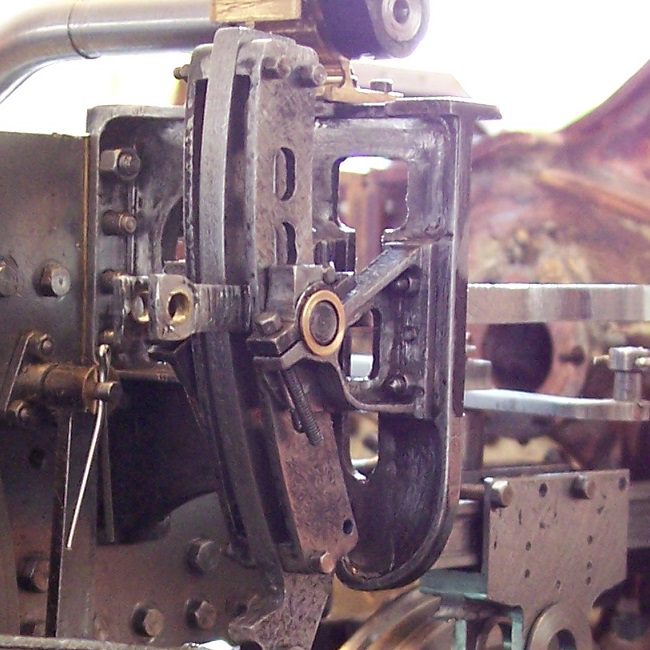

Example 1: ventilation grille with long narrow bars

The ventilation grille, 300 mm high, 600 mm long, is to be cut from 10 mm steel. The five bars are only 4 mm wide and 560 mm long. Here it is very likely that the webs will warp due to the heat input and will not be parallel. Since it is difficult to straighten the bars due to the lack of space, deviations can hardly be remedied afterwards. Therefore, this workpiece should not be produced in this way.

There are a number of ways to make the workpiece more producible. The material thickness could be reduced or the webs widened. It would also be possible to draw in some crossbars. If the dimensions have to remain unchanged, only the frame can be cut, and you cut the rods from a rectangular rod 4 x 10 mm and weld them in (or the locksmith will do that). In order to find the correct position, you can make notches in the frame.

These are the limit values for web widths:

Warnings:

Material thickness up to 3 mm: web width less than twice the material thickness Material thickness over 3 mm: web width less than one and a half times the material thickness

Error:

Material thickness up to 3 mm: web width less than half the material thickness Material thickness over 3 mm: web width less than a quarter of the material thickness

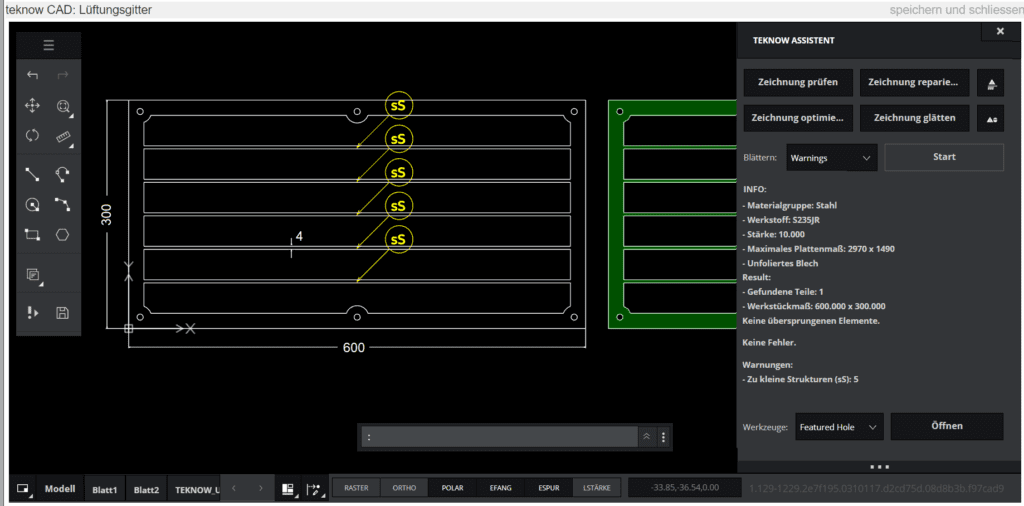

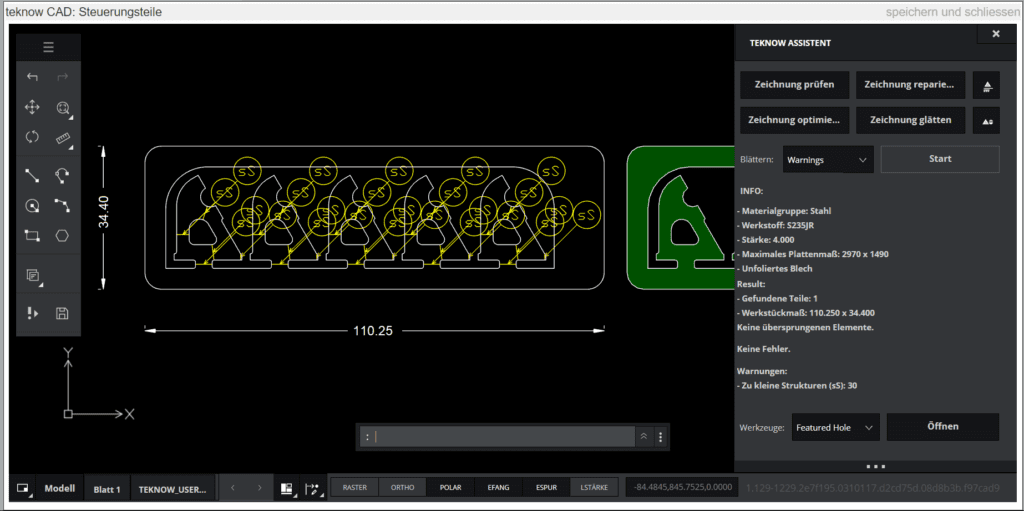

Example 2: mechanical parts

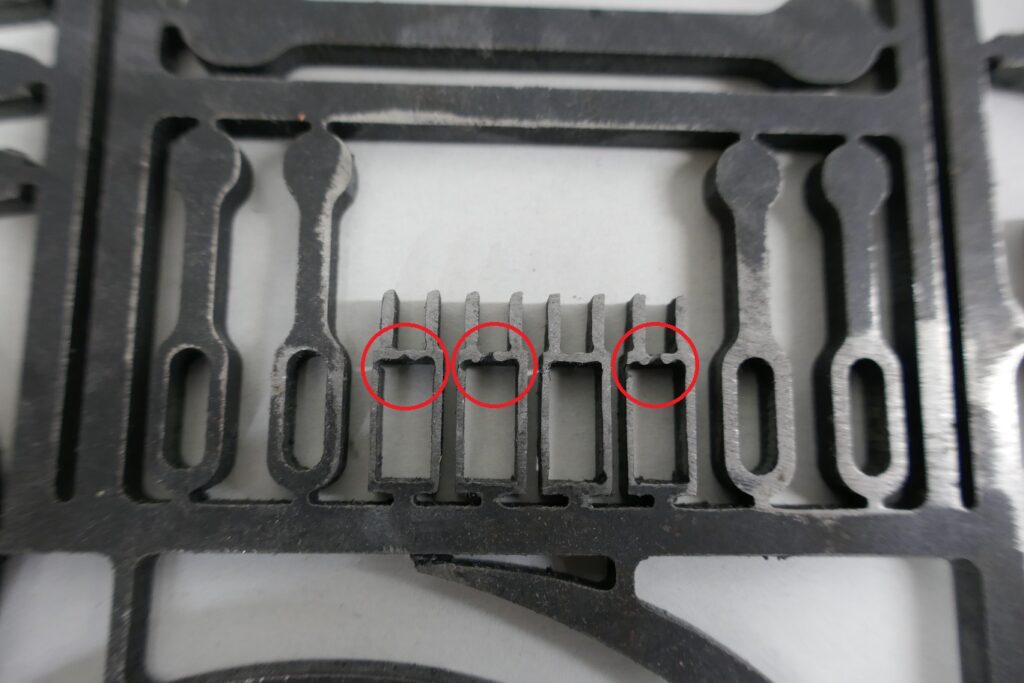

The parts belong to a locomotive model. They are arranged in a frame so that they can be clamped more easily for further processing. A relatively large number of warnings are displayed in these two drawings because the parts are repeated several times.

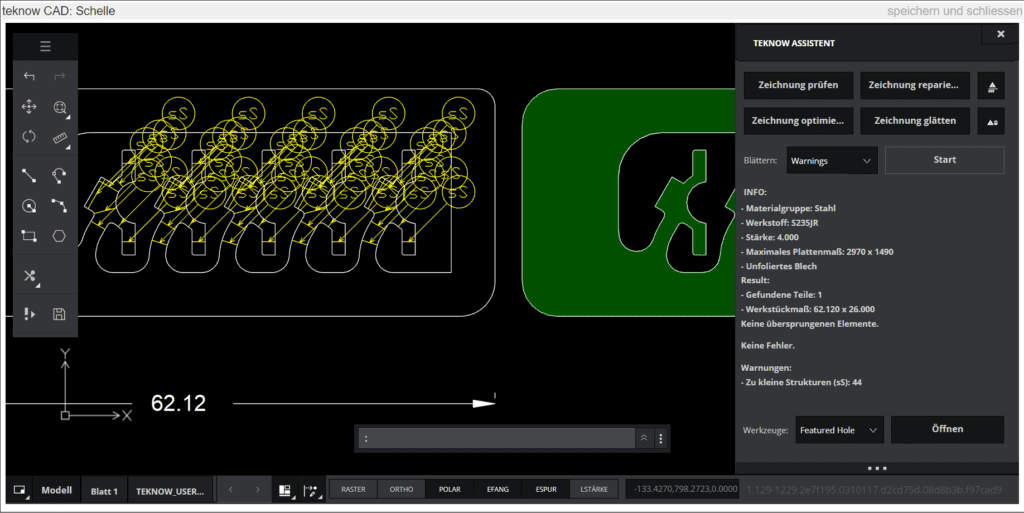

Some of the warnings concern the connections between the parts and the frame – these can usually be ignored, as it is just an auxiliary construction that will be removed later. There are also warnings that concern the actual parts. Here you have to weigh up. In this case, the parts are difficult to produce “by hand”. They will be processed further below, which gives the opportunity to correct distortion or melting. Any discoloration is irrelevant. A few more parts are produced to compensate for failures. The parts could be manufactured and processed with a little loss, as the following two pictures show: on the left the parts in the finished state, on the right installed.

The parts on the following picture show examples of light melts. In this case the result was usable.

Such defects on parts that are no longer reworked and that should have a high optical quality are not acceptable. An example of such a part is a doorbell sign or a plate that contains filigree letters.

Unfortunately that doesn’t work – the cutouts fall into the waste boxes under the machine, together with the cutting slag. The boxes are emptied at the end of the week, there is then nothing more to assign, and it no longer looks good. Furthermore, the cutouts each have the recess somewhere, that is the point at which the laser drills into the sheet metal and the cutting contour starts, so they are not optically perfect.